Precise dust control, purification workshop's' invisible guardian - MX fabric air duct system '

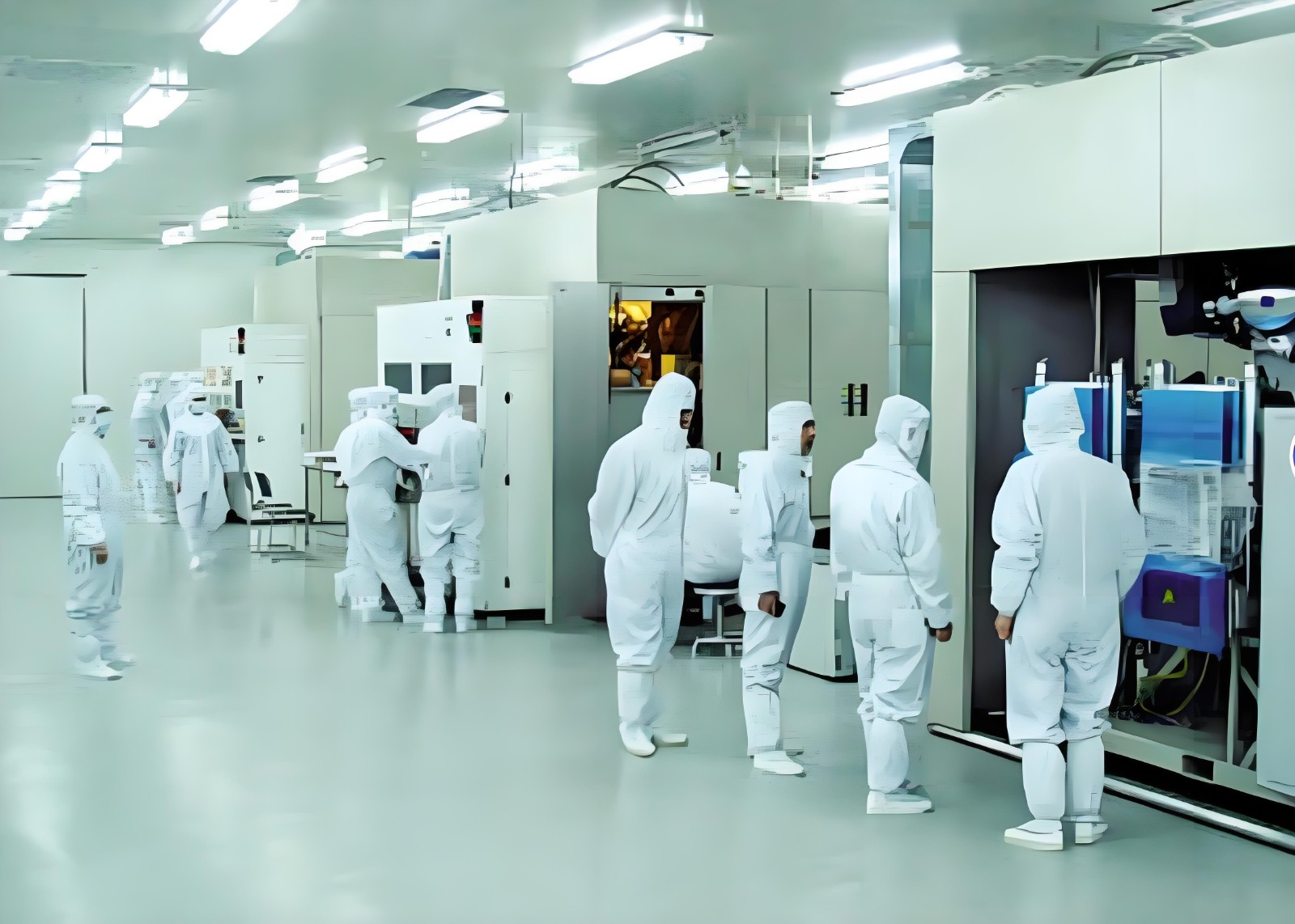

In modern industrial production, cleanrooms have extremely high requirements for air cleanliness, especially in the semiconductor, pharmaceutical, food, precision manufacturing and other industries, where tiny dust or microorganisms may affect product quality. Although traditional metal air ducts are strong and durable, they have many limitations in cleanliness control, airflow organization optimization, installation and maintenance. Fabric air ducts are gradually becoming an ideal choice for cleanrooms due to their unique material properties and air supply methods.

一、Challenges of cleanrooms and limitations of traditional air ducts

In cleanrooms, air cleanliness is usually measured by ISO 14644-1 or GMP (Good Manufacturing Practice for Pharmaceuticals) standards, which require that the concentration of particulate matter and microorganisms in the air be controlled at extremely low levels. Although traditional metal air ducts can transport air, they have the following problems in actual applications:

1. Uneven airflow organization. Metal air ducts adopt a rigid structure and fixed air outlets, which can easily lead to uneven airflow distribution. The wind speed in some areas is too high, while other areas may form vortices, affecting cleanliness.

2. Easy to accumulate dust and difficult to clean. Metal air ducts are prone to dust accumulation. After long-term use, bacteria may breed, increasing the risk of secondary pollution.

3. High energy consumption. Due to uneven airflow distribution, it is often necessary to increase the air supply volume to meet the cleanliness requirements, resulting in increased energy consumption.

4. Complex installation, heavy metal air ducts, long installation cycle, and difficult later maintenance.

These problems have prompted the industry to look for more efficient air supply solutions, and fabric ducts have become the preferred solution for clean rooms due to their flexibility, uniform air supply and easy cleaning.

二、 Advantages of fabric ducts, how to meet the stringent requirements of cleanrooms?

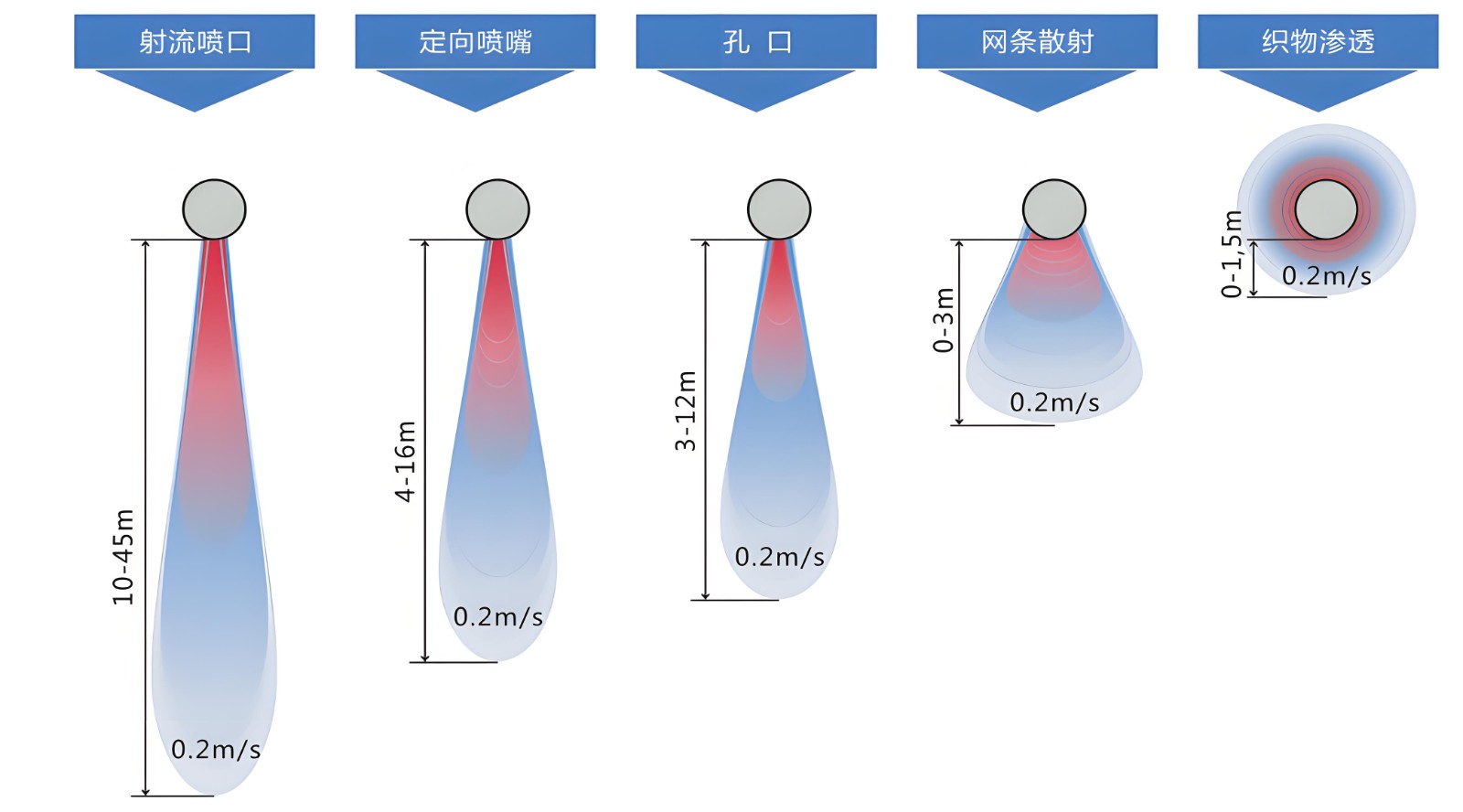

1. Uniform air supply, precise dust control

Fabric ducts use infiltration or orifice air supply, and the air diffuses evenly through the fiber pores to form a three-dimensional air supply in space, and the wind speed is precisely controlled, effectively avoiding the "jet" phenomenon of traditional ducts. This air supply method can not only reduce eddy currents and prevent dust from spreading disorderly in the workshop; it can also maintain a constant wind speed to ensure that the cleanliness of each work area meets the standard. In addition, it can also be applied to different cleanliness levels to meet the stringent requirements of semiconductor, pharmaceutical and other industries.

2. Anti-static, antibacterial, reduce secondary pollution

Purification workshops have extremely high requirements for microbial and static control. Fabric ducts can use anti-static fibers + antibacterial coatings to effectively inhibit bacterial growth and prevent static electricity from adsorbing dust. For example,

The pharmaceutical industry uses FDA-certified antibacterial materials to avoid microbial contamination.

The electronics industry uses anti-static fabrics to prevent static electricity from damaging precision electronic components.

3. Easy to clean and maintenance-free

The interior of traditional metal ducts is difficult to clean, while fabric ducts can be disassembled and washed, and even support high-temperature sterilization (such as food and pharmaceutical industries), which greatly reduces maintenance costs.

4. Energy saving and consumption reduction, reducing operating costs

Since fabric ducts deliver air evenly, unnecessary air volume waste can be reduced. When used with variable frequency fans, energy consumption can be reduced by 20%-30%. In addition, its lightweight design reduces the load on the duct system and further optimizes energy consumption.

5. Flexible installation to adapt to different workshop layouts

Fabric ducts are light in weight and can be suspended, attached to the ceiling or installed along the wall, suitable for various complex spaces. In renovation projects, there is no need for large-scale disassembly and assembly, and they can be deployed quickly, shortening the construction period.

三、 Practical application cases

Case 1, Xinxiang Lelian (Tianjin) Food Workshop Project

"Xinxiang Lelian (Tianjin) Food Co., Ltd." is the second large central kitchen of Xinxiang Group to enter the Chinese market. The Tianjin project covers an area of 30 acres and a total construction area of 20,000 square meters. The purification level is required to be 100,000

MultiXair fabric duct air supply system design:

1. Use MultiXair high permeability material to prevent ice and frost on the system surface.

2. Use MultiXair-S series oval fabric ducts, the fabric duct system is 1200mm wide and 400mm high.

3. Use a 3-row wire rope suspension system, with hanging points at 3, 9 and 12 o'clock in three rows, hanging on the top, and setting hanging points at the end, stretching and fixing to prevent the end from moving when the fan starts and stops.

4. The static pressure box wind speed is controlled at 4~6m/s, and the fabric duct system inlet wind speed is controlled at 8~10m/s.

5. The air supply mode is infiltration air supply and orifice air supply. The orifices are designed in an S-shaped cross arrangement, and the air supply coverage is wider. In order to avoid dry loss caused by direct cold air blowing on the material, the orifice angle is designed at 30~75 degrees.

Case 2, Sichuan Tianhetang Food Workshop Project

Sichuan Tianhetang Food Co., Ltd. High-end Frozen Food R&D and Production Base Project, the project puts forward the following requirements for the central air-conditioning system:

1. Reduce the dry consumption of items in the warehouse;

2. Neat and beautiful appearance; mildew and antibacterial treatment, excellent air quality; purification level requirement 100,000

3. Duct height control to reduce the load of the building structure;

4. Light weight, easy installation, low construction cost;

5. Low noise.

MultiXair fabric duct air supply system solution:

1. According to the architectural characteristics and air supply requirements of the project, a total of 11 MultiXair fabric ducts are arranged; multi-row orifice air supply (55°, 65°, 75° and 85°) air supply design is adopted to ensure the overall temperature while reducing the dry consumption of items in the warehouse;

2. MultiXair-S series fabric ducts are used, flame-retardant B1 grade material, plus antibacterial and anti-mildew function.

3. In order to reasonably utilize the space, the shelves are used in the cold storage, and the height of the air duct is controlled at 80cm to improve the space utilization rate; the light weight requires less load on the building structure and meets the structural requirements.

4. The cold storage board structure is used on the top of the site, and the double-row aluminum alloy slide rail hanging method is adopted according to the site conditions. The fabric air duct is light in weight and easy to install.

In today's pursuit of higher cleanliness and lower energy consumption, fabric ducts are becoming the "invisible guard" of cleanrooms with their advantages of uniform air supply, easy cleaning, energy saving and environmental protection. Whether it is the semiconductor, pharmaceutical, food or precision manufacturing industry, it can provide more efficient and economical air purification solutions.

If you are planning or renovating a cleanroom, you may consider fabric duct technology to let flexible air supply help your company move towards a cleaner and smarter future! MultiXair fabric duct system has accumulated design and implementation experience of various types of projects at home and abroad, and summarized multiple sets of installation methods for different places. For detailed consultation, call whatsapp